In the field of industrial automation, inverter as a motor drive equipment, widely used in all kinds of mechanical equipment. However, in practical applications, overcurrent tripping is a common and complicated problem. Through several practical cases, this paper analyzes the causes and solutions of over current tripping of frequency converter in detail, providing reference for the majority of engineering and technical personnel.

Case 6: Rotary kiln 90kW converter overcurrent trip

Fault symptom: The "OC" overcurrent is frequently skipped, and the overcurrent value is as high as 330A.

Fault analysis: frequency converter capacity is not enough.

Troubleshooting: Replace 160kW inverter, troubleshooting.

Summary: The frequency converter capacity should be selected according to the maximum load instantaneous current.

Case 7:110KW Fuji Pump inverter overcurrent trip

Fault phenomenon: frequency converter often reported over current tripping.

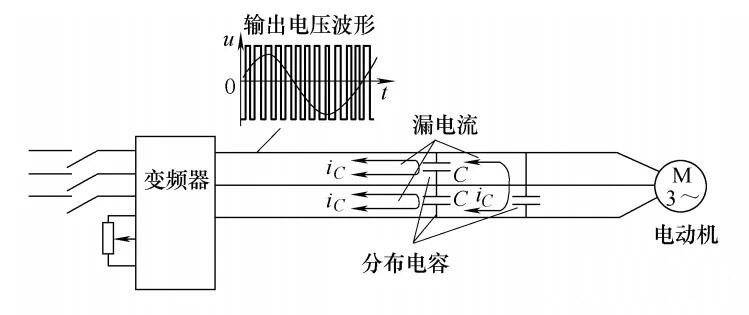

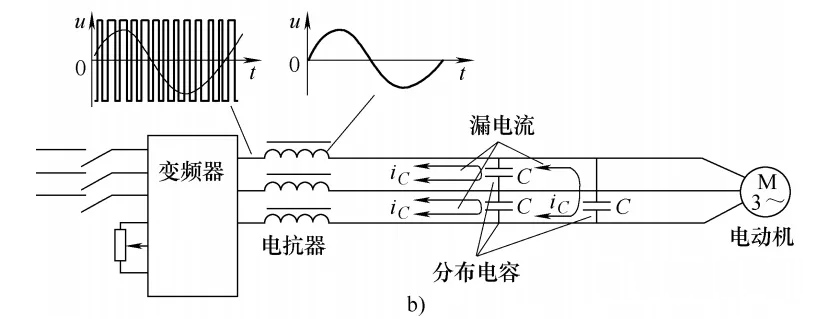

Fault analysis: The cable is too long, caused by the leakage current generated by the distributed capacitance.

Troubleshooting: Add an AC reactor at the output end of the inverter to filter out PWM high order harmonics and troubleshoot.

Summary: The distributed capacitance of the long cable can cause the frequency converter to trip over current.

Case 8: Fujifilm 11kW inverter overcurrent trip

Symptom: The overcurrent trips frequently, and OC is displayed.

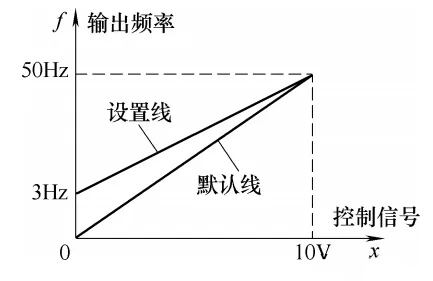

Fault analysis: Improper setting of frequency control characteristic line.

Troubleshooting: Change the forward bias of the frequency control characteristic line to the factory setting, and the fault is rectified.

Summary: Unreasonable parameter setting will also cause the frequency converter overcurrent.

Case 9: Steel mill 220kW ABB inverter over current trip

Fault phenomenon: overcurrent tripping occurs when the machine is started.

Fault analysis: encoder damaged, no speed feedback signal.

Troubleshooting: Replace the rotary encoder and remove the fault.

Summary: In vector closed loop control, encoder damage can cause the inverter overcurrent trip.

Case 10: Danvers 37kW inverter overcurrent trip

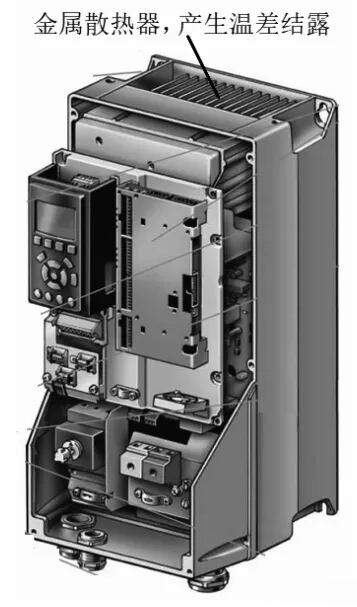

Fault phenomenon: discharge sound occurs in the morning startup, and then the inverter burns.

Fault analysis: Temperature difference condensation causes short circuit of module.

Troubleshooting: prevent condensation, and power on after the equipment and indoor temperature balance.

Summary: Condensation can cause device damage.

Conclusion

Through the above case analysis, we can see that the causes of inverter overcurrent trip are various, including motor winding short circuit, improper parameter setting, load characteristics mismatch, long cable distribution capacitance. According to different fault causes, the corresponding solutions can effectively avoid the frequency converter overcurrent tripping and ensure the normal operation of the equipment. It is hoped that the case analysis of this paper can provide useful reference for the majority of engineering and technical personnel.