In the field of industrial automation, inverter as a motor drive equipment, widely used in all kinds of mechanical equipment. However, in practical applications, overcurrent tripping is a common and complicated problem. Through several practical cases, this paper analyzes the causes and solutions of over current tripping of frequency converter in detail, providing reference for the majority of engineering and technical personnel.

Case 1: Water Bureau 45kW Siemens 430 inverter overcurrent trip

Fault phenomenon: When the frequency converter is turned on, the output frequency rises to 16Hz, and the frequency converter overcurrent trips.

Fault analysis: Centrifugal pump at 16Hz when the current is very small, will not cause overcurrent trip. Suspected short circuit in motor winding.

Troubleshooting: Disconnect the motor, and the inverter runs normally without load. After replacing the motor, the operation is normal. Disassemble the motor and find a short circuit in the winding.

Summary: The pump in the low-frequency case of over-current trip, the main reason may be the motor blocking or winding short circuit.

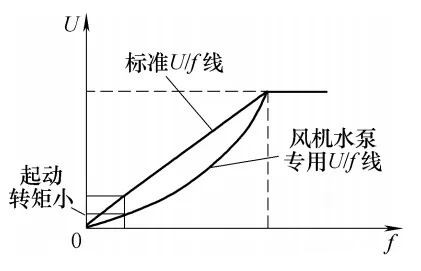

Case 2: Metal processing enterprise 75kW Schneider inverter overcurrent trip

Fault phenomenon: The frequency converter jumps "OCF" during the starting process and cannot work.

Fault analysis: The load is constant torque characteristic, suspected motor winding short circuit.

Troubleshooting: Disconnect the motor, the frequency converter works normally. There is no short-circuit phenomenon in measuring the winding resistance of the motor, but there is a short-circuit burn mark in the winding when disassembling the motor.

Summary: The insulation performance of the old motor decreases, and the PWM waveform of the frequency converter causes the short circuit between turns of the motor.

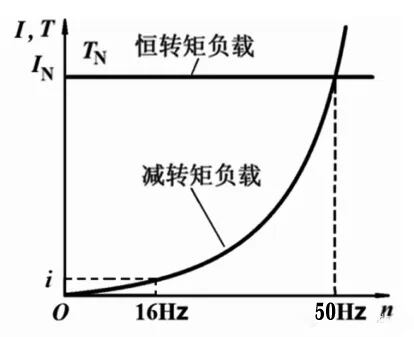

Case 3: Slurry pump 90kW Fujifilm inverter overcurrent trip

Fault phenomenon: When the frequency is about 12Hz, the motor is blocked and the inverter overcurrent is tripped.

Fault analysis: The initial pressure is large, causing the motor to block the rotation current.

Troubleshooting: Change the torque lift code to 0.0, select the automatic torque lift mode, and the motor starts normally.

Summary: In some special occasions, torque improvement should be carried out according to the actual situation.

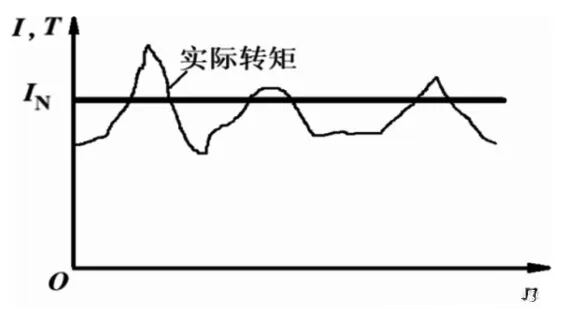

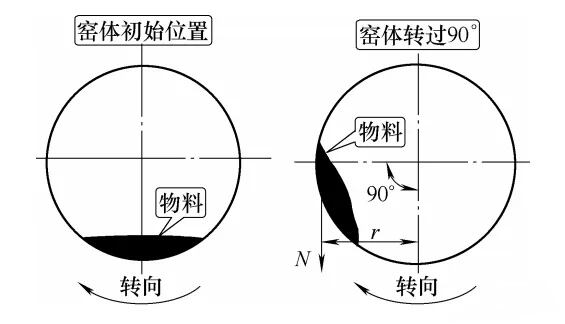

Case 4: Cement rotary kiln 110kW motor overcurrent trip

Fault phenomenon: the frequency rises to about 10Hz, and the motor locked-converter overcurrent protection trips.

Fault analysis: The additional resistance torque caused by the gravity of the material is large, resulting in overcurrent tripping.

Troubleshooting: Adjust the frequency ratio U/f line of the inverter, set the low frequency torque compensation, and start successfully.

Summary: Low frequency torque compensation can solve the problem of overcurrent when starting.

Case 5: Panasonic Electric 3.7kW inverter overcurrent trip

Fault phenomenon: the motor does not turn, but keeps shaking, and shows overload.

Fault analysis: the acceleration time is set too short, the torque lifting level is set too large.

Troubleshooting: Adjust the acceleration time and torque lifting level parameters to appropriate values, and the motor starts normally.

Summary: Improper parameter setting will lead to over current tripping of the inverter.

Conclusion

Through the above case analysis, we can see that the causes of inverter overcurrent trip are various, including motor winding short circuit, improper parameter setting, load characteristics do not match and so on. According to different fault causes, the corresponding solutions can effectively avoid the frequency converter overcurrent tripping and ensure the normal operation of the equipment. It is hoped that the case analysis of this paper can provide useful reference for the majority of engineering and technical personnel.