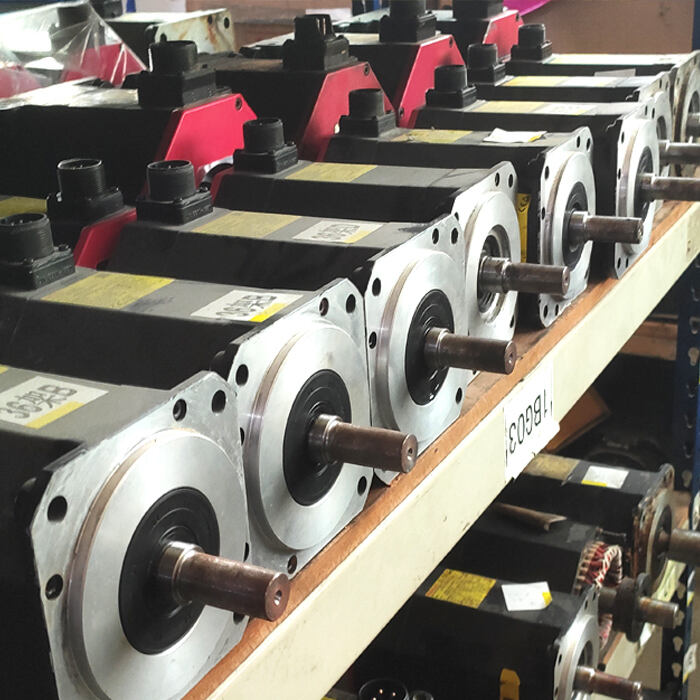

fanuc servo motor

FANUC servo motors represent the pinnacle of precision motion control technology in industrial automation. These advanced motors combine sophisticated digital control systems with robust mechanical engineering to deliver exceptional performance across diverse applications. The motors feature high-resolution encoders that provide accurate position feedback, ensuring precise movement control down to microscopic levels. With their compact design and high power density, FANUC servo motors efficiently convert electrical energy into mechanical motion while maintaining optimal torque output throughout their operating range. These motors excel in maintaining consistent performance under varying loads and speeds, making them ideal for complex manufacturing processes. They incorporate advanced thermal management systems and reliable bearing designs that contribute to extended operational lifespan. The motors' integrated digital interface enables seamless communication with FANUC controllers, facilitating real-time monitoring and adjustment of operational parameters. Their applications span across numerous industries, including automotive manufacturing, aerospace components production, electronics assembly, and precision machining operations. The motors' ability to perform rapid acceleration and deceleration while maintaining positioning accuracy makes them essential in high-speed automation systems.