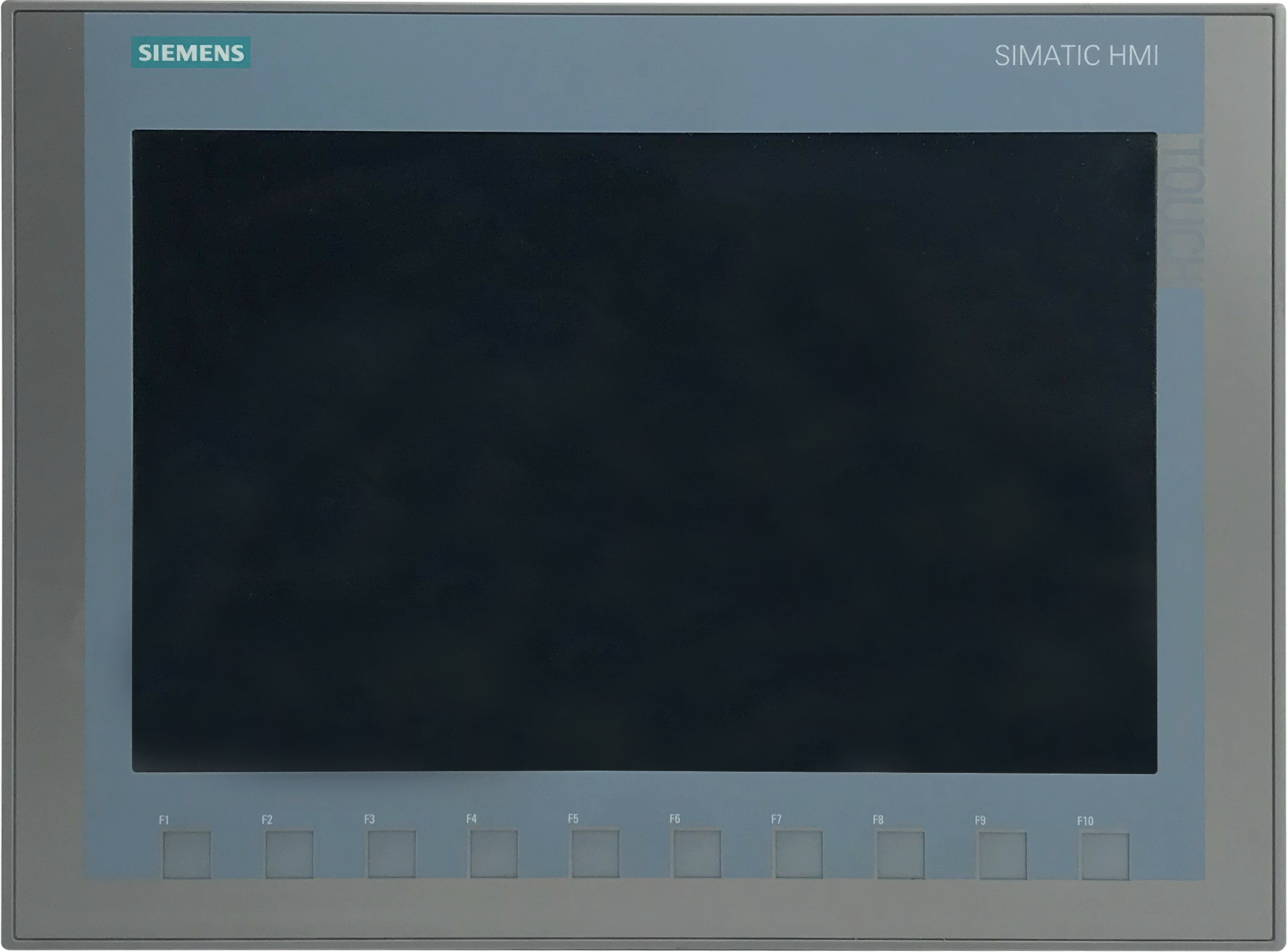

siemens plc

The Siemens PLC (Programmable Logic Controller) represents a cutting-edge automation solution that combines robust hardware with intuitive software interfaces. This advanced control system serves as the backbone of industrial automation, offering comprehensive control capabilities for manufacturing processes, assembly lines, and complex industrial operations. The system features state-of-the-art processors that can handle multiple tasks simultaneously, supported by expandable I/O modules that allow for flexible system configuration. With integrated communication protocols including PROFINET, PROFIBUS, and Industrial Ethernet, Siemens PLCs ensure seamless connectivity across various industrial networks. The system's programming environment, primarily TIA Portal, provides user-friendly tools for configuration, programming, and diagnostics. Modern Siemens PLCs incorporate advanced security features to protect against cyber threats, while maintaining high reliability and system availability. These controllers excel in data collection and analysis, supporting Industry 4.0 initiatives through their ability to process and transmit real-time operational data. The systems scale from compact solutions for simple automation tasks to high-performance controllers capable of managing entire production facilities.